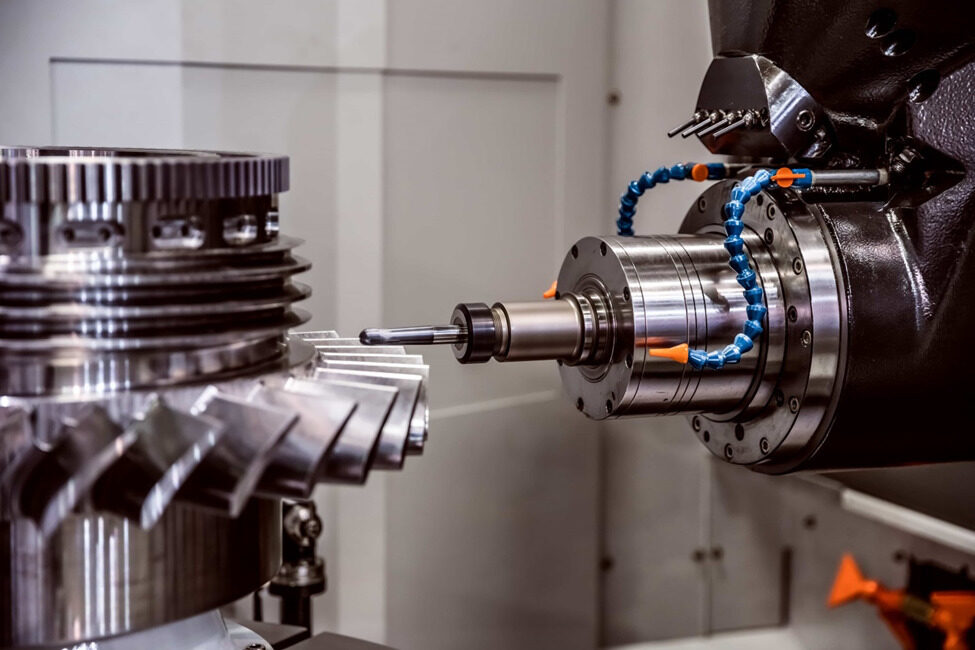

Facilities: 3 & 4 axis CNC, Oblique-guide CNC, Automatic Mechanical Arm Production Line, CNC Turning, CNC Milling.

We can produce everything from sourcing material, coatings, stress relieve, and machining in our facility according OEM’s specification.

Contact us today to discuss what we can do for you.

The company equipped with 3 automatic mechanical arm production lines, 6 oblique guide CNC Lathes, 13 normal CNC lathes, 5 sets of 4 axis vertical CNC, milling machines and drilling machines.

Machining precision can be reached about 0.01mm.

We engaged in machining parts from steel bar and plate, and the final machining for the casting & forging blank.

Certificated by ISO9001:2015 & IATF16949-2016 Quality Management System.

With the aim of improving our production capacity and growing our experience to deal our clients’ various projects, we are constantly learning and studying. In addition, the introduction of advanced equipment also enhances our various production capabilities.

Better solution is always our aim since the beginning of our company. Our solutions are specifically tailored to our clients’needs.

Raw material quality confirmation is the first and important step.

Staffs are trained regularly by the certification authority.

Facilities maintained regularly.

Professional engineer designs reasonable production plans.

Measuring tools are regularly calibrated by the third-party.

Satisfied after-sales service.

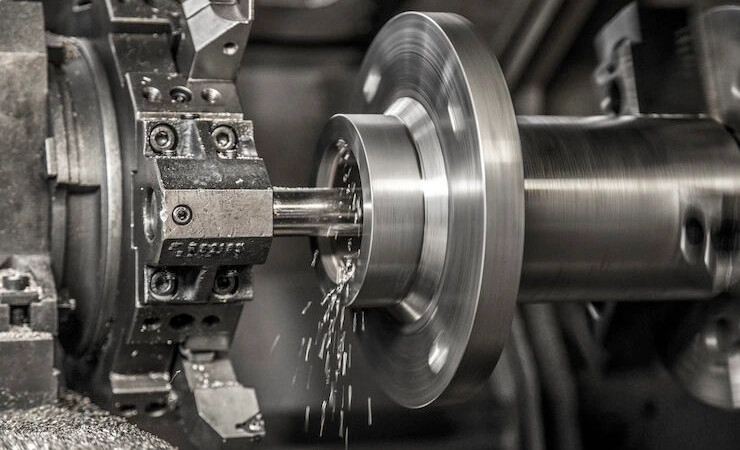

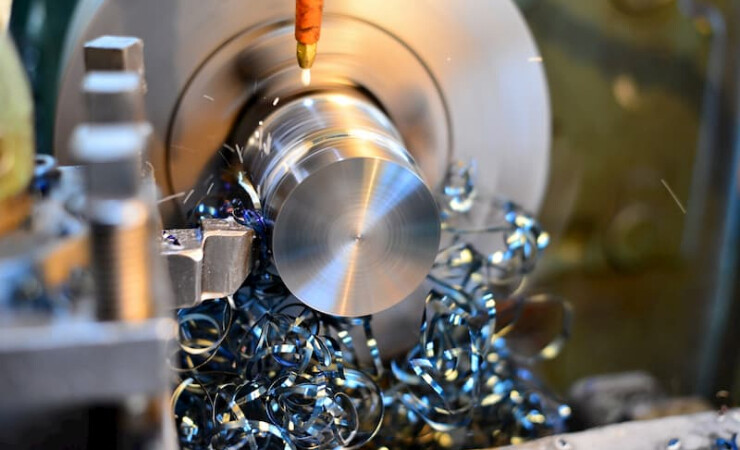

Ningbo Yinzhou Gain Machinery Co., Ltd processes all of the latest CNC lathes. CNC lathes are operated with Computer Numerical Control (CNC) systems and are machine tools where the material or part is clamped and rotated by the main spindle, while the cutting tool that work on the material, is mounted and moved in various axis. So we can accommodate CNC turning jobs of all types requirements.

By the way, we introduced 3 sets of automatic mechanical arm production lines last year, it expands our production capacity and improves production efficiency.

* Equipped with 13 sets of normal CNC Lathe

* Precision of equipment: 0.03-0.05mm

* Working travel: Min: φ20mm, Max: φ800mm

* Degree of surface texture:Ra1.0-1.6

Normal CNC lathes can not deal customers’ comprehensive & complicated projects, such as with tight tolerance, high concentricity requirement, multiple verticality requirements, so we introduces 6 sets of inclined rail machining centers, compared with normal CNC lathe, advantages of inclined rail machining center are:

* Places the traditional guide rails below and behind the workpiece, which greatly increases the chip removal space when the workpiece is turned, so that the chip removal is smoother and the chip holding space is larger, and the accumulation of iron chips is avoided.

* Greatly improve the production accuracy, by reducing product clamping times.

* Tolerance can be reached: 0.01-0.03mm

4-axis machining can be used as a more economically viable way of machining parts theoretically possible on a 3-axis machine. Because it eliminates the need for fixture change-overs, reducing costs even further. Eliminating the risk of human error meant we machined the part to a high quality with no need for expensive Quality Assurance investigations. Removing the need to change fixtures has the additional benefit that tighter tolerances can be held between features on different sides of the part. Loss of accuracy due to fixturing and re-setup has been removed.

* Equipped with 5 sets of 4 axis CNC

* Working travel: 1300mm×φ750mm

* Degree of surface texture: Ra3.2

* Precision of equipment: 0.01mm