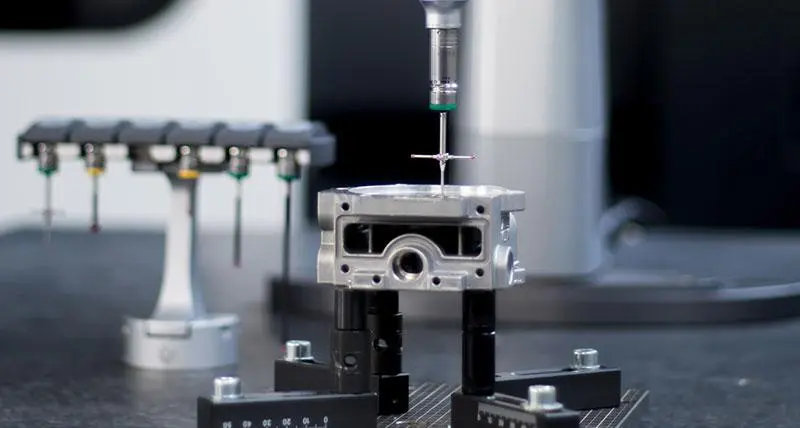

Coordinate inspection results are not the most accurate. Although CMM is a high-precision measurement method, its accuracy and precision are affected by a variety of factors, including machine accuracy, operator skills, environmental conditions, choice of inspection method, and the process of data processing and analysis. The following are a few key factors that affect the accuracy of CMM results:

* Machine accuracy: The accuracy of the CMM machine depends on the precision of its mechanical structure, electronic components, sensors, etc. The machine itself needs to have as little error as possible. The error of the machine itself needs to be as small as possible to ensure the accuracy of the measurement results.

* Operator: The operator needs to be professionally trained and qualified, and the technical level and standardization of the operation process have a direct impact on the accuracy of the test results.

* Environmental conditions: Coordinate testing needs to be carried out in a constant temperature, no vibration, no pollution environment to ensure that the test results are not disturbed by the environment.

* Detection methods: According to different accuracy requirements to choose the appropriate detection methods, such as point cloud matching, curve fitting, etc., to ensure the accuracy of the test results.

* Data processing: Data processing and analysis need to be based on strict standards and processes to ensure the reliability of the measurement results.

In addition, the problem of measurement error of CMM has always existed, in order to further improve the application value of this equipment, relevant scholars have proposed corresponding compensation methods for all kinds of errors of CMM, so as to eliminate all kinds of errors as much as possible and get accurate results. Therefore, although the CMM is a high-precision measurement method, its results are not absolutely accurate, but a series of measures and methods are needed to ensure its measurement precision and accuracy.