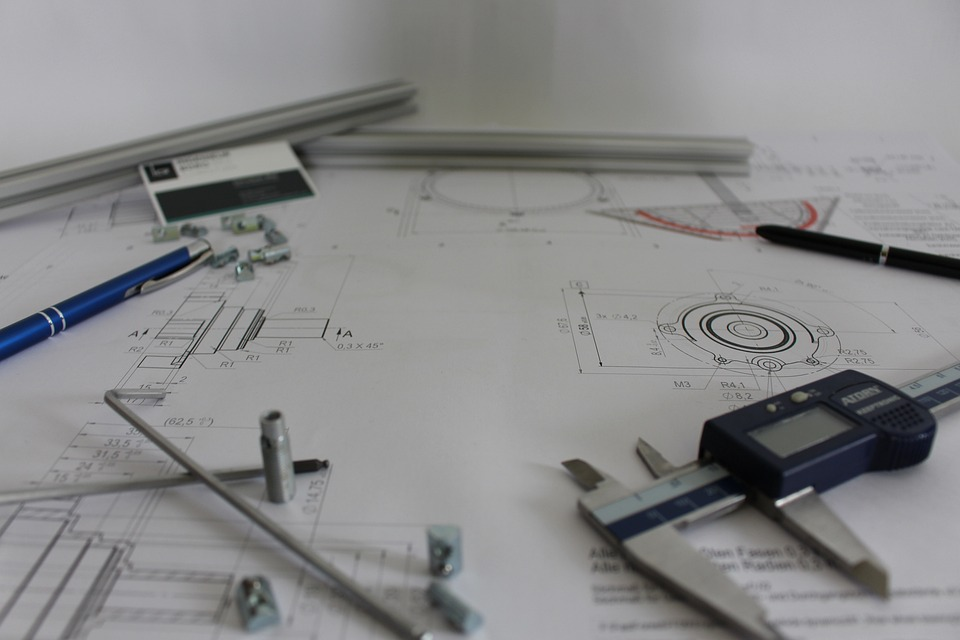

Technical drawing continues to be an important aspect of the machining industry. It plays a key role in guiding manufacturers to ensure that machined parts meet the required specifications. More specifically, technical drawing with engineering graphics contains information that serves as a visual and communication tool for manufacturers and engineers during various machining processes.

As such, this article provides a complete overview of technical drawing in the machining industry, including its importance, common drawing standards and conventions, and tips for creating accurate and effective engineering drawings.

What is Technical Drawing?

Also known as engineering drawings in the machining industry, technical drafting refers to the creation of detailed, precise and accurate illustrations of parts and assemblies to be manufactured. These drawings provide a clear view of the part to be machined by providing key information about dimensions, annotations, tolerances, surface finish, and other features required during the machining process.

Machinists, designers, architects and engineers use technical drawings as a communication tool to convey information and ideas. Knowing how to read technical drawings helps ensure that a part meets its design requirements and is suitable for its intended use. These accompanying drawings are clear and follow specific standards, conventions and symbols to ensure that the information conveyed is accurate, consistent and easy to understand.

As a result, engineering drawings make it easier for machinists to keep track of various manufacturing items, provide accurate production cost estimates, and reduce the likelihood of misunderstandings or errors during the manufacturing process.

The Importance of Technical Drawings in the Machining Industry

Technical drawings have been around for a long time and have been drawn by hand for centuries. Nonetheless, these drawings still serve multiple purposes in today’s machining industry. Check out some of the benefits of technical drawings in the machining industry:

- Accuracy and precision

Technical drawings are critical to ensuring the accuracy of machined parts. Technical drawings provide detailed information about the dimensions and tolerances of the part, ensuring that the machinist produces a part that meets the required specifications. Additionally, without accurate and precise technical drawings, machinists would have to rely on guesswork, which could result in producing parts that do not work as intended.

- communication

Technical drawings are a communication tool that allows designers, engineers and machinists to convey their ideas. This information is vital for the machinist to understand the requirements of the part and machine it to the required specifications.

- Efficiency

Technical drawings are vital for improving the efficiency of the machining process. They reduce the need for iterations and enable the machinist to produce a part that meets the required specifications on the first attempt. This increases the efficiency of the machining process and reduces the time and production costs of customised mass production.

- Quality Control

Technical drawings are an important part of quality control in the machining industry. Technical drawings provide standards for measuring and testing machined parts. In addition, these drawings enable quality control inspectors to verify that machined parts meet required specifications before use.

Types of Machining Engineering Drawings

There are different types of engineering drawings used in the machining industry, each of which serves a unique purpose in the design and manufacturing process. These drawings provide machinists with the information necessary to create parts that meet design requirements. Below are some examples of technical drawings used in the machining industry:

- Orthogonal drawing

Orthogonal or multi-view drawings are still the most common type of technical drawing in the machining industry. These dimensioned 2d drawings provide a detailed and accurate representation of the shape, size, angles, and dimensions of a part in 2D form. In addition, orthogonal drawings show front, top, and side views of the part, each representing a different plane. 2.

- Isometric Drawing

Isometric drawings are 3D representations that show the part to be manufactured. As such, they provide a more realistic representation of the component, making it easier to visualise and understand its key features. Isometric drawings are particularly useful for complex parts that have irregular shapes or are difficult to visualise in orthogonal drawings.

- Decomposition Diagrams

Decomposition drawings show where the individual parts of an assembly are located and how they fit together to form the final product. These drawings are particularly useful for complex assemblies, enabling the machinist to understand how the parts fit together and how they are assembled.

- Cutaway Drawings

Sectional drawings show a cutaway view of a part, revealing its internal structure and how it fits together. They can be valuable illustrations for parts with complex internal structures or parts whose internal assembly is critical to the function of the part.

Why you need the accuracy and precision of technical drawings

Technical drawings are used to communicate the design of a part to a machinist, and any errors in the drawings can result in a part being machined that does not meet the required specifications. For this reason, accuracy and precision remain two key components of technical drawing in the machining industry. This is why accuracy and precision are critical in technical drawing:

- Ensuring part functionality

Accurate and precise technical drawings enable machinists to create parts that function as they should. Any deviation from the required specifications can result in a part that does not work as intended, which can lead to major problems on the production line.

- Waste reduction

Producing parts that do not meet the required specifications wastes time, effort and materials. Accurate and precise technical drawings help reduce waste by ensuring that parts are machined correctly. This reduces the need for rework, which can be costly.

- Meeting quality standards

Accurate and precise technical drawings help ensure that machined parts meet the required quality standards. More importantly, machining parts to the necessary design specifications also helps prevent defects that could lead to failures and ensures that the part operates as intended.

Application of technical drawings in machining

Technical drawings are applicable to various machining processes. Check the following:

Turning and milling

Technical drawings are vital in turning and milling operations as they specify the required surface finish and other critical features. This in turn ensures that the final product meets the required specifications.

Drilling

Technical drawings are vital in drilling as they provide the machinist with the dimensions and tolerances needed to machine the required holes. This includes the size, depth and location of the hole.

Other common applications include grinding and electrical discharge machining (EDM).

Conclusion

Technical drawings are an important aspect of the machining industry. As an important part of quality control, technical drawings enable machinists and inspectors to ensure that parts meet the required specifications. There are different types of technical drawings, each with unique uses in the design and manufacturing process.

Most importantly, contact us and let our expert technicians help you analyse your technical drawings and provide expert design advice to ensure an efficient and cost-effective manufacturing process.